Every day, millions of people in the U.S. take generic drugs instead of brand-name ones. It’s not because they’re cheaper alone-it’s because the FDA makes sure they work just as well. If you’ve ever wondered whether that $4 generic version of your prescription is really the same as the $50 brand, the answer isn’t guesswork. It’s science, regulation, and years of rigorous testing backed by data.

What Makes a Generic Drug the Same?

A generic drug isn’t just a copy. It’s a legally approved version of a brand-name drug that must meet exact standards set by the FDA. The active ingredient-the part that actually treats your condition-must be identical in chemical structure, strength, dosage form, and route of administration. If your brand-name drug is a 20 mg tablet taken by mouth, the generic must be the same: 20 mg, tablet, oral. No exceptions. The FDA doesn’t require generic manufacturers to repeat the expensive animal and human trials the original drug went through. Instead, they use a shortcut called the Abbreviated New Drug Application (ANDA). But don’t let the word “abbreviated” fool you. This process is one of the most tightly controlled in all of medicine.Bioequivalence: The Core of Generic Approval

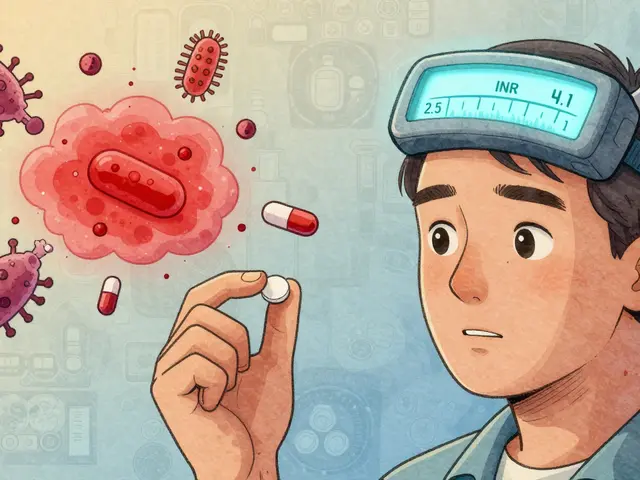

The biggest question is: Does your body absorb the generic drug the same way it absorbs the brand? That’s where bioequivalence comes in. To prove this, manufacturers run clinical studies with 24 to 36 healthy volunteers. These volunteers take both the brand-name drug and the generic, in random order, under controlled conditions-sometimes fasting, sometimes after eating, depending on the drug. Blood samples are taken over time to measure how much of the drug enters the bloodstream and how fast. The FDA requires the generic’s absorption to fall within 80% to 125% of the brand’s. That’s not a rough estimate-it’s a strict statistical range. The 90% confidence interval for two key measurements-AUC (total exposure over time) and Cmax (peak concentration)-must both land inside that band. If even one result is outside, the application is rejected. For most drugs, this range is wide enough to account for normal human variation. But for drugs with a narrow therapeutic index-like warfarin, levothyroxine, or lithium-where tiny differences can cause harm, the FDA tightens the rules. Since 2019, these drugs must show bioequivalence within 90% to 111%. That’s a much narrower margin, and it’s based on real clinical risk.Manufacturing: Same Standards, Different Factory

You might think the brand-name drug is made in a fancy lab while the generic comes from a sketchy factory. That’s not true. All manufacturing facilities-whether for brand or generic-must follow the same Current Good Manufacturing Practices (cGMP), enforced by the FDA. Inspectors show up unannounced at least once every two years. They check everything: raw materials, equipment calibration, cleanliness, packaging, and even how workers handle samples. Every batch must meet USP <905> standards for content uniformity: no more than 85% to 115% of the labeled amount. That’s tighter than most food safety rules. Even inactive ingredients (fillers, dyes, preservatives) are tracked. The FDA maintains an Inactive Ingredient Database with safe limits for over 500 excipients across 80 different delivery methods. If a generic uses a new excipient, the manufacturer must prove it’s safe at that dose. That’s why some generics look different-color, shape, or size-but contain the exact same active ingredient.

The ANDA Process: A Step-by-Step Gauntlet

Submitting an ANDA isn’t like sending an email. It’s a 30,000- to 50,000-page dossier. The bioequivalence section alone can be 5,000 to 10,000 pages of raw data, graphs, and statistical analysis. The process has clear stages:- Filing Review (60 days): The FDA checks if the application is complete. In 2022, 35% were refused outright for missing key data or incorrect format.

- Substantive Review (8-10 months): Teams of chemists, pharmacologists, and biostatisticians examine every detail. They look at manufacturing processes, stability data, labeling accuracy, and bioequivalence results.

- Facility Inspection: About 21% of rejections in 2022 came from inspection findings-cleaning procedures, equipment validation, or record-keeping issues.

- Approval or Complete Response Letter (CRL): If there are problems, the FDA issues a CRL. Common reasons: flawed bioequivalence studies (28%), manufacturing flaws (22%), or labeling errors (18%). Fixing these often adds 6 to 12 months.

Real-World Evidence: Do Generics Actually Work?

Some people say, “My generic doesn’t work like the brand.” You hear it in pharmacies, on Reddit, even from doctors. But what does the data say? A 2023 IQVIA study tracked 15 million patients using common drugs like atorvastatin and metformin. No difference in outcomes. In fact, adherence was 3.2% higher with generics-because people could afford to keep taking them. The FDA’s Adverse Event Reporting System shows generic drugs have the same rate of side effects as brand-name ones: about 1.6 to 1.7 reports per million prescriptions. Still, some experts point to rare cases. For complex products-like inhalers, topical creams, or injectable emulsions-small differences in how the drug is delivered can matter. That’s why the FDA created the Complex Generic Drug Product Initiative in 2022. They’ve issued 27 new guidance documents since then to help manufacturers nail these tricky formulations. And yes, 37% of pharmacists say patients report concerns. But when those reports are checked against lab results, almost none show clinically meaningful differences. Perception doesn’t always match reality.

Laia Freeman

29 Jan 2026 at 21:22OMG I CANNOT BELIEVE THIS!! I thought generics were just cheap knockoffs 😱 But now I’m like… wait, the FDA is basically a drug superhero?? Like, they check EVERYTHING?? I’m gonna start asking for generics on purpose now. My wallet and my brain are both so happy. 🙌💊