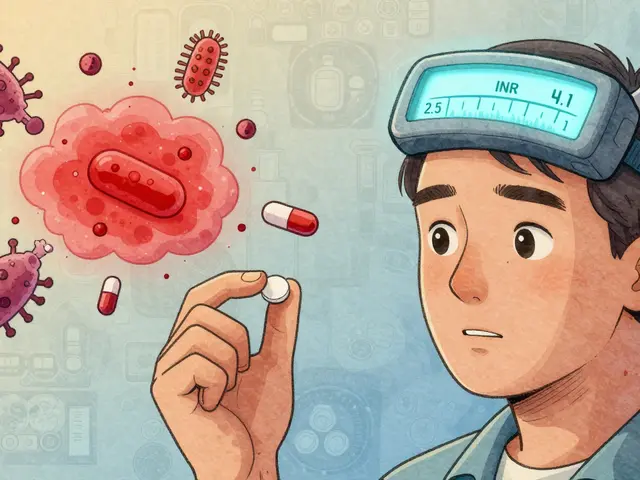

When you pick up a generic pill at the pharmacy, you expect it to work just like the brand-name version. But behind that simple tablet or capsule is a complex manufacturing process-and it’s far more prone to failure than most people realize. In 2023, generic drug defects led to over 1,800 adverse event reports in the U.S. alone, with patients describing crumbling tablets, uneven coloring, and unexpected side effects. These aren’t isolated mistakes. They’re symptoms of a systemic problem in how generic medicines are made.

What Goes Wrong in Generic Drug Manufacturing?

Generic drugs aren’t copies of brand-name drugs in the way a photocopy is a copy. They’re supposed to match the active ingredient, strength, and performance. But the manufacturing process is where things fall apart. Unlike branded drugs, which often have dedicated production lines and higher budgets for quality control, generics are squeezed for cost at every step. This pressure leads to four main types of defects: physical flaws in the tablet, contamination, dosing errors, and labeling mistakes.Take capping, for example. This is when a tablet splits horizontally during compression. It happens when the powder mixture is too dry (moisture below 2%) and the machine presses too hard-over 15 kN of force. The result? A broken tablet that may deliver half the dose-or none at all. In one 2023 batch of generic metformin ER, pharmacists reported tablets crumbling during dispensing. That’s not a handling issue. That’s a manufacturing failure.

Lamination is similar but involves layers peeling off. It’s common in extended-release tablets and often occurs when turret speeds exceed 40 rotations per minute without proper pre-compression. Then there’s sticking, where the active ingredient clings to the machine’s punch heads. This happens when the drug has a low melting point (under 120°C) and the environment has too much moisture (over 4%). The machine keeps pushing out tablets, but the drug is literally sticking to the tools, causing inconsistent dosing.

And then there’s mottling-uneven color on the tablet surface. It doesn’t affect potency, but patients notice it. They think the pill is spoiled, even if it’s not. In one FDA inspection, a batch of generic levothyroxine showed severe mottling. Patients reported feeling “different” on the new batch. The manufacturer insisted it was safe. But trust matters as much as chemistry.

Why Are Generic Drugs More Prone to Defects?

Branded drug companies spend 15-18% of their production budget on quality control. Generic manufacturers? Often 8-10%. That gap isn’t small. It’s the difference between real-time weight monitoring systems and manual checks every hour. It’s the difference between automated visual inspection (detecting defects as small as 0.1 mm) and human inspectors who miss up to 30% of flaws.According to FDA data from 2019 to 2023, generic facilities failed inspections at more than double the rate of branded ones: 57% versus 28%. Why? Three reasons:

- Price pressure: Generic drugs are sold at 80-90% discounts. To stay profitable, manufacturers cut corners on equipment upgrades, staff training, and environmental controls.

- Shared facilities: Many plants make dozens of different generics in the same building. Cross-contamination is a real risk. One facility in India was shut down in 2023 after traces of a blood pressure drug were found in an antibiotic batch.

- Aging equipment: The average tablet press in a U.S. generic plant is over 20 years old. Modern machines monitor compression force within ±10% of target. Older ones drift. And if punch length isn’t kept within ±0.05 mm, you get weight variation that breaks pharmacopeial limits.

And it’s not just the U.S. The European Medicines Agency found similar trends. In 2023, 37% of rejected generic drug certifications were due to manufacturing defects-up from 29% in 2019.

Which Generic Drugs Are Most at Risk?

Not all generics are created equal. Some are simple-immediate-release tablets with one active ingredient. Those have a defect rate of about 9.3%. But complex formulations? They’re a minefield.- Inhalers: Defect rate of 18.2%. Tiny dose inconsistencies can mean the difference between relief and a hospital visit for asthma patients.

- Modified-release tablets: 14.7% defect rate. If the coating fails, the drug releases too fast-or not at all.

- Sterile injectables: 8.7% defect rate. A single particle of glass or metal in an IV bag can cause sepsis. These are the most dangerous.

Recall data backs this up. In 2023, 63% of generic drug recalls were due to manufacturing defects-compared to 41% for branded drugs. And the top three reasons? Weight variation, particulate contamination, and inadequate sterilization.

Real-World Impact: What Patients and Pharmacists Are Seeing

Behind every defect is a person. In a 2023 survey of 1,247 U.S. pharmacists, 68% reported encountering quality issues with generics in the past year. Forty-two percent said patients complained about tablet appearance-cracks, discoloration, odd shapes. Twenty-nine percent said patients reported unexpected side effects or lack of effect.On Reddit’s r/pharmacy, a thread from January 2024 titled “Generic drug quality getting worse?” had 287 comments. One pharmacist wrote: “Received a batch of generic levothyroxine from a new supplier. Five patients came back saying they felt jittery, even though their TSH levels were stable on the old batch. We switched them back. No one complained after.” Another: “Metformin ER tablets from a new lot literally fell apart when I opened the bottle. I called the manufacturer. They said it was ‘within acceptable limits.’”

Hospital formulary committees now track these reports. In 2023, 17.3% of requests to substitute a brand drug with a generic included quality concerns. Nearly 10% of those resulted in permanent retention of the brand version-because the risk was too high.

What’s Being Done to Fix It?

There’s hope-but it’s slow. The FDA launched its Emerging Technology Program in 2023. So far, 47 generic manufacturers have adopted continuous manufacturing, a process that cuts defect rates by 65% compared to old batch methods. It’s like switching from hand-stitching clothes to using a high-speed sewing robot.AI-powered inspection systems are also starting to appear. Pilot programs at Sandoz and Dr. Reddy’s show 92% defect detection accuracy-far better than human inspectors. But these systems cost hundreds of thousands of dollars. Most small generic makers can’t afford them.

The 2024 Drug Supply Chain Security Act now requires track-and-trace for high-risk generics. Early results show a 22% drop in counterfeit-related quality issues. That’s progress. But it doesn’t fix poor manufacturing.

The real fix? Investment. The Generic Pharmaceutical Association estimates it would take $28.7 billion to upgrade all U.S. generic manufacturing facilities to modern standards. Right now, the industry spends $1.2 billion a year. That’s not enough.

What You Can Do

If you’re a patient: If your generic medication suddenly feels different-less effective, more side effects, or looks different-tell your pharmacist. Don’t assume it’s “in your head.” Document the lot number. Report it to the FDA’s MedWatch system.If you’re a healthcare provider: When switching patients to generics, note the manufacturer. If a batch causes problems, flag it. Many hospitals now maintain “preferred generic” lists based on quality performance, not just price.

And if you’re wondering whether generics are safe? Most are. But safety isn’t guaranteed. It’s earned-through investment, oversight, and accountability. The system is broken in places. But awareness is the first step to fixing it.

Are generic drugs less safe than brand-name drugs?

Not inherently. Generic drugs must meet the same bioequivalence standards as brand-name drugs. But manufacturing defects-like inconsistent dosing, contamination, or tablet flaws-are far more common in generics due to lower quality budgets and aging equipment. So while the active ingredient is the same, the risk of a faulty batch is higher.

What are the most common physical defects in generic tablets?

The top four are capping (tablet splitting), lamination (layer peeling), sticking (drug adhering to machine parts), and mottling (uneven color). These are caused by poor powder flow, incorrect moisture levels, machine speed issues, or outdated presses. They don’t always affect potency, but they erode patient trust and can signal deeper quality problems.

Why do generic drug recalls happen more often than brand-name ones?

Because generic manufacturers operate under extreme price pressure, they often cut corners on equipment maintenance, staff training, and environmental controls. FDA data shows 63% of generic recalls stem from manufacturing defects-compared to 41% for branded drugs. Shared facilities and aging machinery also increase contamination and inconsistency risks.

Which generic drugs have the highest defect rates?

Inhalers (18.2% defect rate), modified-release tablets (14.7%), and sterile injectables (8.7%) are the most vulnerable. These require precise manufacturing controls. Even small errors can lead to underdosing, overdosing, or contamination-especially dangerous for patients with chronic conditions.

Can I trust a generic drug if it looks different?

Appearance alone doesn’t mean it’s unsafe-color and shape can change between manufacturers. But if the tablet is cracked, crumbling, discolored, or has an odd texture, it could indicate a manufacturing defect. Report it to your pharmacist and check the lot number. Don’t ignore changes in how you feel after switching generics.

What’s being done to improve generic drug quality?

The FDA is pushing for modern manufacturing, like continuous processing and AI-powered inspection systems, which can cut defect rates by 65% or more. The 2024 Drug Supply Chain Security Act also improves traceability. But progress is slow. Most manufacturers still use outdated equipment because upgrading costs millions-and generic prices won’t cover it.

What’s Next for Generic Drug Quality?

The future of generics depends on whether regulators, manufacturers, and payers can align on quality-not just cost. The FDA’s 2024-2027 plan aims to reduce quality-related shortages by 30%. That’s possible-if investment catches up. But if nothing changes, McKinsey & Company predicts 15-20% of generic manufacturers will exit the market within five years, not because they’re unprofitable, but because the cost of recalls and failures is unsustainable.Patients shouldn’t have to choose between affordability and safety. But right now, that’s the reality. The solution isn’t to abandon generics-it’s to demand better manufacturing. Because when a tablet cracks, it’s not just a defect. It’s a risk to someone’s health.

Chris & Kara Cutler

31 Jan 2026 at 22:11Ugh, I just got a batch of generic metformin that looked like it was crushed by a toddler. 🤢 Took me 20 mins to swallow one without it crumbling. My pharmacist said "it's fine"-yeah, fine for them, not for me.